The Ultimate Overview to Welding Inspection Racine for Industrial Standards

Wiki Article

Enhance Quality Control and Conformity Standards With Professional Welding Assessment Providers

Specialist welding inspection solutions play a critical function in making certain that these requirements are fulfilled with accuracy and accuracy. As we browse through the complexities of welding evaluation solutions, it comes to be obvious that the experience and focus to detail offered by professionals in this field are vital for maintaining the highest possible standards of quality and compliance.Importance of Welding Examination Solutions

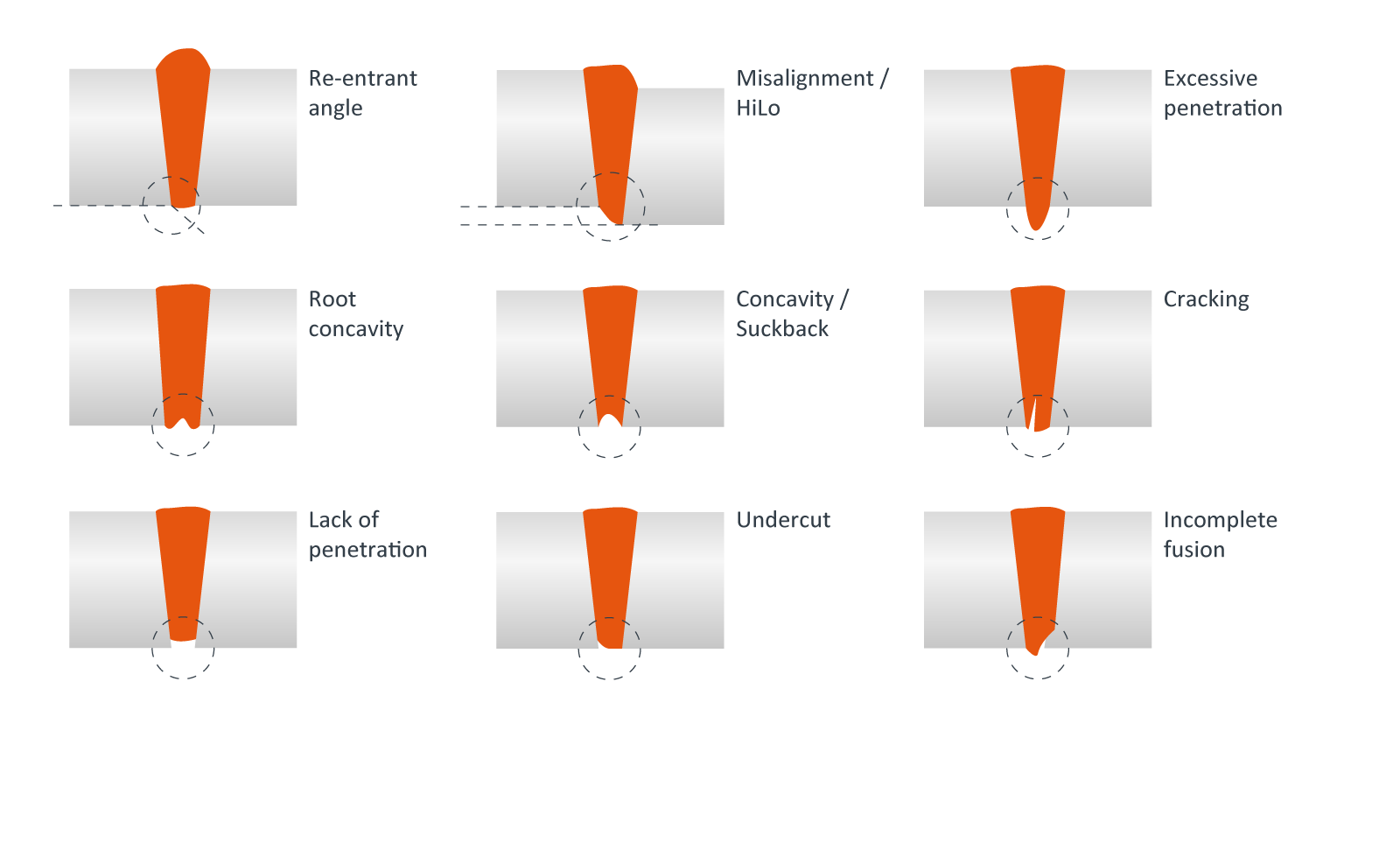

Ensuring the high quality and security of welded structures, welding evaluation services play a vital duty in different markets. By conducting comprehensive inspections, these services assist in determining any welding defects, gaps, or flaws that can jeopardize the stability of the framework - Welding Inspection Racine. Welding examinations are necessary for preserving compliance with sector criteria and guidelines, as well as ensuring the long life and integrity of the welded componentsOne vital relevance of welding assessment services is the avoidance of potential risks and accidents. By spotting welding imperfections beforehand, these solutions assist in reducing dangers connected with structural failures, leaks, or other functional concerns. Furthermore, welding inspections aid in maximizing the total performance and efficiency of welded frameworks, adding to set you back savings and enhanced productivity for businesses.

In addition, welding inspection solutions supply a degree of guarantee to stakeholders, demonstrating a dedication to high quality and safety and security standards. With detailed inspections and reporting, these services make it possible for business to construct trust fund with customers, regulators, and the public, inevitably boosting their reputation and trustworthiness in the marketplace. Finally, the value of welding inspection services can not be overstated, as they are vital for upholding quality, security, and compliance in welding procedures across sectors.

Advantages of Expert Assessment

One of the primary benefits of experienced assessment services is the very early discovery of welding problems, which helps stop costly rework or repair services down the line. Experienced assessments assist support compliance with relevant codes and standards, safeguarding the credibility of the business and cultivating a society of excellence in welding techniques. Overall, investing in professional welding evaluation solutions yields long-lasting benefits by promoting adherence, performance, and security to industry best methods.Conformity With Sector Criteria

One of the basic columns of keeping the architectural honesty and quality control in welding procedures is straightening with sector requirements. Compliance with sector criteria is critical for guaranteeing that welding treatments fulfill the necessary criteria for safety, performance, and resilience. These standards are developed to control the welding process, products utilized, security protocols, and overall quality assurance measures. By following sector criteria such as those set by organizations like the American Welding Society (AWS) or the International Company for Standardization (ISO), business can demonstrate their dedication to creating top notch welds that satisfy or surpass the necessary specs.Furthermore, conformity with sector requirements not only makes sure the security and reliability of bonded frameworks but also boosts integrity and trust fund with clients, regulative bodies, and other stakeholders. It represents a dedication to quality and professionalism and trust in welding techniques, which can set a company apart in an open market. Generally, aligning with market requirements is necessary for supporting quality control, accomplishing regulative conformity, and fostering a track record for quality in welding processes.

Enhancing Top Quality Control Measures

Improving weld quality assurance actions is paramount for making sure the integrity and safety of welded structures. By improving quality assurance procedures, firms can minimize defects, decrease rework, and eventually supply premium products to their customers. One efficient means to boost quality assurance steps is to execute thorough inspection procedures throughout the welding process. This consists of evaluating raw products prior to welding, keeping track of the welding specifications during Visit Website the procedure, and performing post-weld inspections to find any kind of issues or blemishes.

Furthermore, buying advanced welding modern technologies and tools can also considerably improve high quality control procedures. Automated welding systems, for instance, can give even more regular and specific welds contrasted to manual welding processes - Welding Inspection Racine. Additionally, giving routine training and certification programs for welders can make certain that they are current with the current methods and standards, further boosting the high quality of welds

Improving Product Safety And Security and Performance

Improving product safety and efficiency is necessary in making certain the dependability and durability of bonded structures. By purchasing professional welding inspection services, suppliers can considerably improve the overall top quality of their items. Via extensive assessments and adherence to conformity standards, prospective problems or weak points in the welding procedure can be identified and remedied quickly, inevitably enhancing the security and efficiency of the end product.

Improving product safety and efficiency is necessary in making certain the dependability and durability of bonded structures. By purchasing professional welding inspection services, suppliers can considerably improve the overall top quality of their items. Via extensive assessments and adherence to conformity standards, prospective problems or weak points in the welding procedure can be identified and remedied quickly, inevitably enhancing the security and efficiency of the end product.Item safety is vital in sectors where welded structures are thoroughly used, such as building, auto, and aerospace. Any concession in the welding honesty can lead to devastating effects, including structural failures and security threats. Therefore, prioritizing welding examination solutions not only guarantees compliance with sector laws but also imparts self-confidence in the see this here item's reliability and performance (Welding Inspection Racine).

In addition, by proactively addressing any welding defects or disparities, makers can boost the general high quality of their products, causing raised consumer satisfaction and trust. Better item safety and security and performance additionally add to lasting cost savings by decreasing the chance of rework, repair work, or item failings. In conclusion, buying professional welding assessment services is a positive technique to assuring the safety and security, integrity, and performance of welded structures.

Final Thought

To conclude, specialist welding examination solutions play an essential duty in ensuring conformity with sector criteria, improving top quality control procedures, and enhancing item security and performance. With the help of these solutions, business can preserve premium quality assurance degrees and satisfy governing requirements, ultimately leading to much better products and enhanced consumer complete satisfaction.

As we browse through the intricacies of welding assessment services, it comes to be obvious that the competence and interest to information offered by specialists in this field are important for preserving the highest possible standards of quality and conformity.

Ensuring the high quality and safety and security of welded frameworks, welding examination services play a critical role in different markets.In addition, welding evaluation services supply a degree of assurance to stakeholders, demonstrating a commitment to top quality and safety and security standards. In final thought, the relevance of welding examination solutions can not be overstated, as they are important for maintaining top quality, safety and security, and conformity in welding procedures throughout industries.

Automated welding systems, for example, can offer more constant and exact you can check here welds contrasted to manual welding procedures.

Report this wiki page